proposed a computer model to optimize the position of a group of tower cranes to determine the minimum crossing area. The first method is to minimize the cross area between tower cranes. The previous research on the optimal positioning method of tower crane mainly adopts two methods.

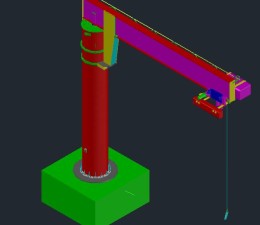

Because there are many types of components transported by tower crane, such as prefabricated components, reinforcement, formwork, and scaffold, and the location of material supply is complex, the positioning and layout planning of tower crane in the construction site of high-rise residence is a common construction technical problem. Tower crane is an essential equipment for the vertical transportation, installation, and positioning of prefabricated components in high-rise residential buildings. It can further enrich the functions of perception, analysis, decision-making, and optimization realize the decision-making intelligence of industrial buildings and achieve the organic unity of engineering construction execution system and decision-making command system. In this study, the vertical transportation and positioning of components are studied, and intelligent construction is formed by integrating information technology. By clarifying the transfer relationship between the component material supply point, the component initial positioning point, and the tower crane optional positioning point, as well as the cooperative relationship between each positioning point and the tower crane operation, the tower crane positioning optimization model is formed, and the firefly algorithm is used to automatically calculate and generate the best positioning layout method of the tower crane on the project site. In view of this, aiming at the current situation that building information modeling (BIM) software can only obtain the relative coordinates of components, this article puts forward the key technology of importing computer-aided design (CAD) graphics into geographic information system (GIS) software to automatically obtain the world coordinate information. This manual method is time-consuming and impractical. The existing tower crane positioning layout mainly depends on the experience of construction personnel, and the best tower crane positioning can be found through a large number of manual data calculation.

0 kommentar(er)

0 kommentar(er)